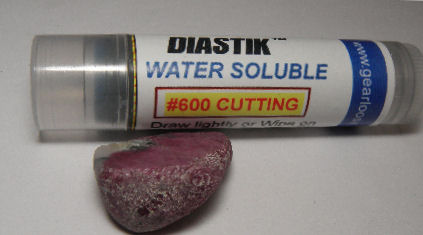

DIASTIK™

1: In self-dispensing tube.2: Contains potent boundary layer lubricants. 3: Very cool-cutting and economical to use. A tiny touch does it.

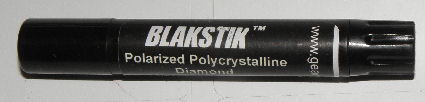

| NEW PRODUCT: July 1, 2013, By Request:100,000 or 200,000 Water-polarized polycrystalline diamond.

Exceptionally fast clean polishing on the Matrix™ and BA5T™ and other laps. Tiny amounts on damp, not wet, lap needed.

NEW PRODUCT:April 28, 2012, By Popular Request:#600 Grit Very High Concentration WATER-SOLUBLE CUTTING Diastik. Use on BATT, Zinc, Copper, etc laps with tiny amount of water. Eats quartzes through sapphire.

Free shipping to US Addresses.

|

Now available on the BATTstore, and now available in #325 and #1,200 Grit, by popular request.

From trimsaw to polish:

This IS a good saw..100 concentration, continuous bronze rim, 320 Grit.

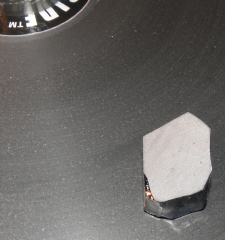

Charging LIGHTLY with the DIASTIK™, 60K Grit size:

The spirals smooth and burnish immediately upon polishing:

40 Seconds at 600 RPM:

Operating experience. (Reproduced by permission, M. Huynh,

2nd Pre-Masters winner, USFG single stone competition 2009 )

I had a (lucky) chance to try Gearloose’s new products; 3K DIASTIK and Battglide cutting fluid as well as 60K DIASTIK. SUMMARY: Corundum was cut with a 1200-grit Crystalite, pre-polished with the 3K DIASITK on a BATT, and polished with the 60K DIASTIK on a Darkside. The Battglide was used on both the BATT and Darkside. I had very good results. I want to share how I did. The material was 10 mm round, ruby-colored synthetic corundum (4.7 carats) that was used for my corundum practice long time ago. The original finish of the stone was pretty bad.

This is how I did: While the BATT lap was turning at the slowest speed, I applied one or two drops of the Battglide and wiped the entire lap with a small piece of paper towel. I rubbed the 3K DIASTIK for a second.

This 3K DIASTIK/BATT step was aggressive enough to remove corundum, but the grit was fine enough to produce smooth pre-polish. It is very desirable for corundum, because the orange peel is inevitable (at least for me) and its removal is essential to produce good final polish.

When the swarf got loaded and the cutting slowed down, I applied one drop of the Battglide, wiped with paper towel, and reapplied a swish of the 3K STIK. The Battglide removed swarf very well. I almost called it “Swarf-Be-Gone”. After this step was done, I wiped the lap with the Battglide and put it back in a designated plastic bag. The Battglide is totally odorless and easy to wipe off the stone.

This is when the break facets were pre-polished with 3K STIK on the BATT.

I did the same with 60K DIASTIK on the Darkside (put a few drops of the Battglide, wiped the entire lap and applied a swish of the 60K STIK). I used medium speeds (3 or 4 of 16 on an Ultra-Tec) and light pressure for both the BATT and Darkside.

When you use DIASTIK, you may see this gunk around the facets. It is no threat. It can be easily wipe-cleaned. The Battglide does not leave a film of fluid like WD-40, which makes polishing imperfections hard to see.

This 60K/Darkside step polishes corundum that has been well pre-polished, but does not cut enough to move around the meets. It is important to remove all the orange peels, previous pits and scratches at the 3K/BATT step. However, the 60K/Darkside can move the meets on other stones. There was no scratch at all at this step .

Of course, corundum can be cut in other ways. But for me, the convenience and ease of the above described methods won me over any other methods, unless Gearloose would come up with something niftier.

*********************************

QUESTIONS? E-MAIL ME !

Back to the BATT Page.